Being a Woodworker is Easy

1 / 57

Half Pencil Marks Exact Copies

While trying to trace an exact copy of the throat plate for my table saw, I came up with this nifty technique using an ordinary pencil. I just shaved my pencil into a half-pencil by carefully grinding it on my belt sander. The flat edge enables my modified pencil to ride straight up along the edge of the template. It also works great for marking and then shaping inlays for my woodworking projects. — Tim Reese.

2 / 57

Perfect Bar Clamp Cover

Iron pipe clamps can easily mar softer woods or react with the glue to stain the wood. My solution is to cut a section of plastic PVC pipe to size and place it around the pipe. If you have several short lengths, you can space them strategically to accommodate different widths of stock wood. — Tim Johnson.

3 / 57

Bonus: Watch this video to see some of favorite woodworking tips in action:

4 / 57

Quick Blade-Height Gauge

This gauge block is the quickest way to set the height of a table saw blade. This one is made from a 3-in. length of 4×4 cut to the settings used most frequently. If you need more settings, just create another block.

Then when it's time to reset the table saw blade, these blocks will help you get the job done quickly

5 / 57

What's the Reason for Nominal Dimensions?

For many of us, the moment we learned that a 2×4 board is actually 1.5 inches x 3.5 inches was simply mind-blowing. The reason for this apparent contradiction is that the board has been planed down to eliminate irregularities. At one point, many years ago, 2x4s actually were 2 inches x 4 inches, but their rough surfaces made them difficult to stock and handle. The old terms, such as 2×4 or 4×4, are still used, and are known as the "nominal" size of the board. These nominal sizes are used because they are easier to say and they stick to tradition.

6 / 57

Flexible Sanding Block from the Office

Sanding curves is tricky. Sometimes you need a sanding pad that's both firm and flexible. A small notepad works great. Just wrap sandpaper around the pad and bend the pad to whatever arc you need. Slip the one end of the sandpaper between the pages to help hold it in place on the pad. Give this a try the next time you're working on a project that has curves and tough to reach spots.

7 / 57

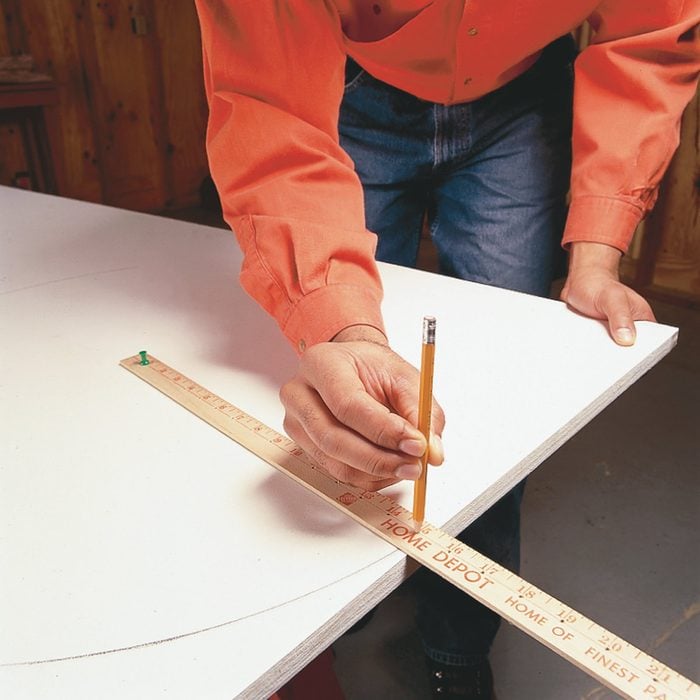

Simple Circle Layout Tool

This simple jig makes laying out circles a breeze. Drill a 1/8-in. hole through every inch mark on a ruler or yard-stick. To draw a circle, place a pin through the number "1" into the center of your board. Add 1 in. to the radius of the circle you wish to draw, and insert a pencil into this number. Using the pin as a pivot, rotate the pencil to mark the circle. — Edwin Constantino.

8 / 57

Make a Quick Mixing Surface

Instead of using a container to mix a small amount of epoxy, just make a mixing surface on your workbench using painters tape. Simply lay down strips, overlapping the edges so the epoxy doesn't get on your bench. When you're done, peel off the tape and throw it away. This mixing surface will work for more than just epoxy, you can use it for wood glue or any other material you need easy access to while working on a project.

9 / 57

Cheap Stain Sprayer

Here's an easier way to stain or seal chairs, lattice or anything with numerous tight recesses. Pour the stain into a clean, empty spray bottle. Spray the stain onto the project and wipe up the excess with a brush or rag. The sprayer will squirt stain into all those tight, hard-to-reach cracks and joints. — Valrie Schuster.

10 / 57

Never-Fail Miter Joint Clamp

Clamping up four mitered corners is tricky. You can buy specialty clamps for this, but I make my own. Here's how to do it: Start with a long 1×4, as it's easier (and safer) to clamp for making the angled cuts than a short piece. Mark out the blocks, and then drill a 1-in. diameter hole in the center of each one. The hole prevents the blocks from getting glued to your project. Cut 45-degree angles tangent to the hole, and then cut the blocks free from the long board.

11 / 57

Slick Table Saw Tip

I find the best way to protect my cast-iron table saw top is to occasionally rub on a coat of paste wax. This gives me a nice, slick top for easier material feeding, and if I drip glue on the surface, it won't stick. It also helps prevent surface rust when the air is humid. — Jack Linden.

12 / 57

Easy Odd-Width Measuring

How do you divide 11-3/8-in. (or any other mathematically difficult number) into equal parts without dividing fractions? Simple. Angle your measuring tape across the workpiece until it reads an easily-divisible dimension and make your marks with the tape angled. For example, say you want to divide an 11-3/8-in. board into three equal parts. Angle the tape until it reads 12-in., and then make marks at "4" and "8".

13 / 57

Safety When Cutting Small Parts

Recently I needed to cut some small furniture legs on my miter saw. With their irregular shape, they were impossible to hold safely, so I attached each leg to a scrap 2×2 with a dowel screw. These assemblies stayed straight and kept my hands far from the blade. — David Alexander.

14 / 57

Improvised T-Bevel

Not long ago, I needed to make some angled wood parts to build a new soffit on my garage. I didn't have the customary tool for the job, but I had some steel joining plates. I screwed through one of the holes in the plate, set my angle, then added another screw to lock the angle. I could then use it as a template to mark all the pieces at the same angle and cut them with my circular saw. — Ryan Bartsch

15 / 57

Bi-Fold Workbench

Old doors laid across sawhorses make great temporary workbenches, but they take up a lot of space when you're not using them. Instead of full-size doors, I use bifold doors with hinges so I can fold them up when I'm done working. They're also easier to haul around in the pickup for on-the-road jobs. — Harry Steele.

16 / 57

What is Quarter-Sawn Lumber?

A board is considered "quarter-sawn" when the growth rings run, more or less, perpendicular to the face of the board. Quarter-sawn boards generally have straight grain and are less prone to shrinkage, compared to other boards. These factors don't come into play with the 2x4s you use to frame a closet—but it does with the shelves and cabinetry you put into that closet; you want those boards to remain straight, flat and stable.

Some quarter-sawn boards, especially those of white oak, exhibit gorgeous rays or flecks; a hallmark of much Craftsman-style furniture. Because of their stability and beauty, quarter-sawn boards are often actively sought out by woodworkers—meaning they may also come with a heftier price tag.

Illustration by Melanie Powell, from "Woodworking FAQ" by Spike Carlsen (Story Publishing, 2012)

17 / 57

On-Hand Sandpaper Cutter

Cutting sandpaper is a quick way to dull your scissors or utility knife blade. Instead, I fastened a hacksaw blade to the edge of my workbench. I slipped a washer behind the blade at each of the mounting holes so a sheet of sandpaper to easily slides in behind the blade. I fold the paper where I want to cut, just as a reference. — Kim Boley.

18 / 57

Make Your Own Table Saw Fence

This self-clamping table saw fence takes only seconds to put on and lets you crank the blade into the fence to create both angled cuts along board edges and extremely thin rip or rabbet cuts. With a hand- or jigsaw, cut pieces from a 1×4, making the inside width of the "L" a hair under the thickness of your saw's fence. Drill 5/16-in. holes in the L-blocks and plywood fence and join them with two 1/4-in. x 3-in. countersunk machine screws, washers and Wing-Nuts. As always, use extra caution when you're sawing without a blade guard. Our thanks for this new sawing angle to professional furniture maker George Vondriska.

19 / 57

That Glue is Still Good!

I recently wrote to the Borden company, asking what to do when their Elmer's wood glue gets too thick to use. They wrote me back and suggested mixing in a drop or two of vinegar. It sounded like an old wives' tale, but I tried it and found it really works.

20 / 57

Brilliant Miter Saw Stop

I use binder clips for a lot of things around the shop, and here's one that I thought I'd share. When I need to make multiple cuts all the same length, I just clamp my jumbo binder clip to my fence and use a 1/4-in.-thick wood scrap pinched in the clip as a stop. Works like a charm! When it's not in use, I clamp it to the cord so it's always nearby. — John Muchow

21 / 57

Align Angles with Tape

Clamping mitered edges can be a real hassle because they never seems to line up correctly. The easiest way that I've found to get around this process is to use painter's tape as clamps. First set the pieces so that the outer edges are facing up and tape them edge-to-edge. The flip the pieces over so the beveled edges are facing up and glue them together. Complete the process by taping the last two edges together and let sit until completed. The tape removes easily and the glue won't attach to the tape, making sanding and finishing very simple.

22 / 57

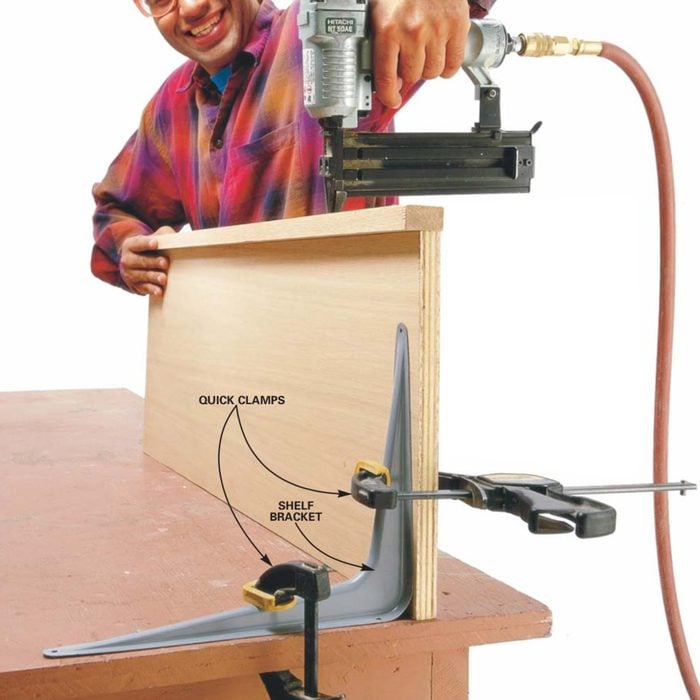

Shelf Bracket to the Rescue

Brace skinny material on edge with this slick system. Clamp a shelf bracket to a workbench, stand the material on edge and then clamp it to the bracket. The clamp will hold the material, keeping your hands free for other operations. — Azha Jensen.

23 / 57

Transportation Flag Clamp

If you have to pick up long lengths of wood from the lumberyard, throw a spring clamp in the back of your vehicle. Use the clamp to attach the warning flag to the end of the protruding lumber. The clamp's easy to slip on and off, and you won't have to fuss around with staples, nails or string. — Steve Parker.

24 / 57

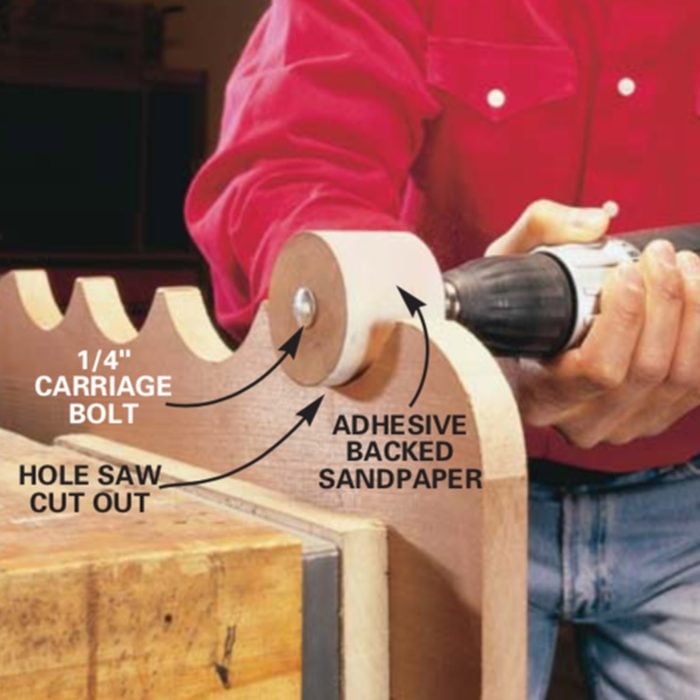

Hole Saw Drum Sander

Sanding the inside of a hole or curved surface can be difficult. To simplify that task, insert a 1/4 x 3-in. bolt into the pilot hole of a hole-saw cutout. Secure the bolt with a washer and nut. Using a hacksaw, cut a 1/4-in. deep slot in line with the bolt. Cut a piece of adhesive-backed sandpaper so that you can slide one end into the slot, wrap it around the cutout, and slide the other end back into the slot. Chuck the bolt into a drill, and you now have a homemade drum sander. — E.R. Comstock.

25 / 57

Hand Plane Hack

Here's a way to joint or shape work pieces that are too small to hold in a vise. Flip a hand plane upside down and clamp it in your bench vise. Now you can pass the wood over the plane to joint the edge. — Matt Boley.

26 / 57

Shop-Made Finishing Standoffs

Tired of waiting for finish to dry on one side before finishing the other side? You can purchase standoffs, but it's also really easy to make them yourself. Simply drive 2-in. drywall screws through 2-in. x 2-in. squares of 3/4-in. thick stock. The screw points will leave a divot in the finish that can be touched up later, but I always let the back side of my project rest on the screws while the finish dries. — Matt Boley.

27 / 57

Visual Aid for Sanding Even Surfaces

With an orbital sander and good sandpaper you can smooth wood evenly and easily with first-class results. When flush-sanding solid edge-banding, draw a squiggly line across the joint before sanding. The edge-banding will be slightly proud of the plywood veneer, so the pencil marks provide a visual aid to make sure that you're sanding flat, and that you don't sand through the plywood's veneer. As you go, you can also test for a smooth, level transition by gently scraping your fingernails against the transition. If it's smooth, your fingers will not catch on the seam between the two pieces

28 / 57

Catch Wood Chips with PVC Pipe

My planer blasts shavings all over the shop floor. I decided to make my own dust chute from 4-in. PVC sewer pipe (which has thinner walls than regular Schedule 40 pipe) and a couple caps. I cut a slit in the pipe and used a heat gun to soften the plastic. That allowed me to open the slit. (Heating PVC releases fumes; ventilation is critical.) I then drilled holes in the flap and screwed it to the planer housing. Finally, I cut a 2-1/2- in. hole in one of the end caps to accept my shop vacuum hose. Works great! — Luis Arce.

29 / 57

Make Your Own Super-Strong Sandpaper

"I do a lot of finish-sanding freehand, without a sandpaper block, so I can smooth edges and get into nooks and crannies. But the finer grits are usually bonded to thinner paper and, at least for me, the paper is too thin and ends up tearing long before the grit wears out. So I apply duct tape to the back of the sandpaper. The sandpaper is still flexible enough to sand a tight radius and it's far more durable. You can use this super-strong sandpaper like a shoeshine rag." — Chuck Merchant

30 / 57

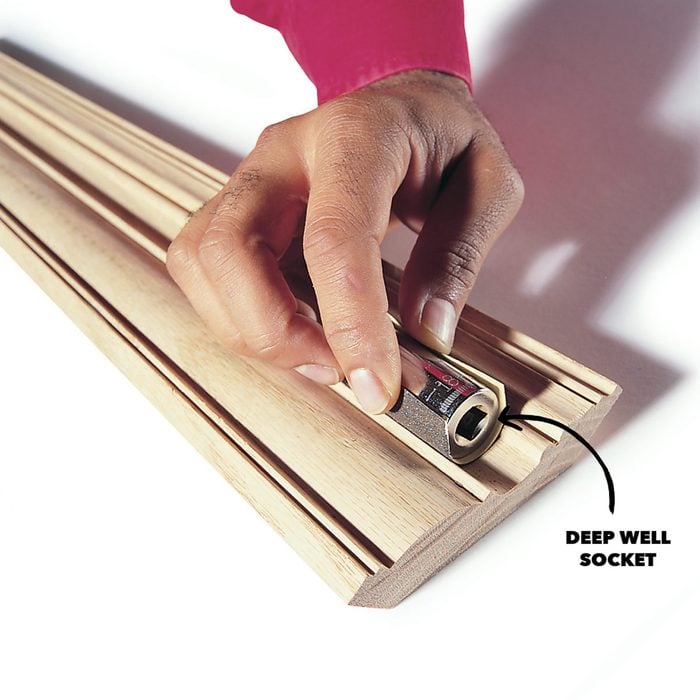

Socket Sander

Sanding concave molding doesn't have to be difficult. Find a deep socket that fits the contour of your molding. Wrap a piece of sand- paper around the socket and hold it in place with your fingers. Your sanding will be uniform and the delicate edges of the molding won't round over. — Eric and Cheryl Weltlich.

31 / 57

No Slipping, No Splinters

To prevent friction burns and splinters while sanding a curved tabletop, I put on a leather glove and wrapped painter's tape around it, sticky side out. The tape kept the sandpaper from slipping, and the glove protected my hand. — Eliot Sennett.

32 / 57

Make a Stain Index

Hard to determine which stain you need in that bespattered collection of cans? An easy-to-make "stain index," courtesy of reader Bob Jacek, solves the problem. Section off boards of your favorite woods into squares with masking tape, and apply the different stains across the width of each wood type (pine, oak, birch, etc.). When the stains are dry, brush on lengthwise your regular finishes—polyurethane, water-based polyurethane, oil, orange shellac, etc. You'll be able to tell how each stain looks with each finish. Label each one. Use both sides of each board, and you'll have a wooden encyclopedia of stain and finish combinations.

33 / 57

Stretchy Clamps

Old bicycle inner tubes work great for clamping odd-shaped projects. I used them recently to hold the rungs secure in a set of chairs I glued up. Just knot the tube to the right size and then stretch it over. Set the chair on a flat surface as the glue dries. The tubes can handle jobs that conventional clamps just can't. — Allen J. Muldoon

34 / 57

Make a Mixing Block

I mix a lot of epoxy in small batches, but I've seldom had the right size container on hand. I solved this problem by drilling 1-1/2-in. holes in 2×4 scraps with a Forstner bit. The resulting shallow "cups" allow easy mixing without the risk of spilling. When the holes are used up, I just make a new mixing board. — Bill Wells.

35 / 57

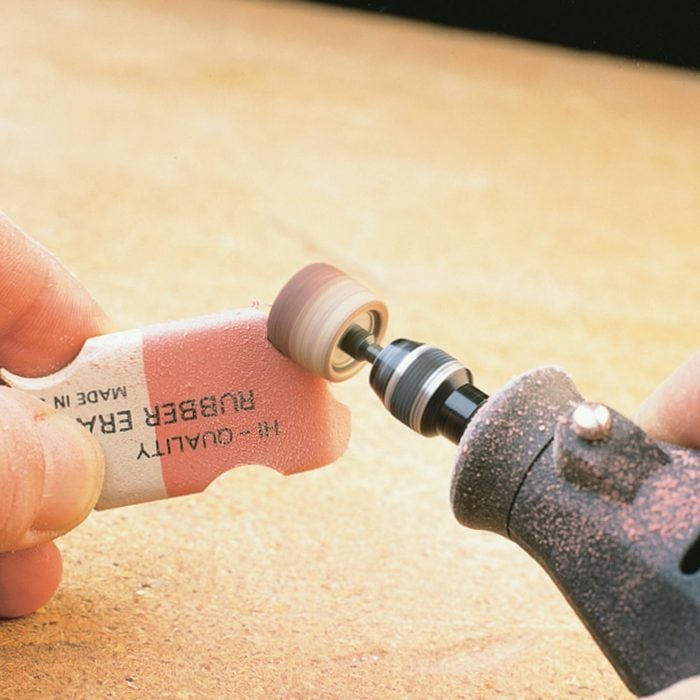

How to Clean Your Mini Drum Sander

When your rotary tool's sanding drum gets clogged, refresh the surface with a rubber pencil eraser. Run the tool at low speed and press the eraser into the clogged drum to rub out the chips and gunk. Check out this pencil hack for perfectly flat boards.

36 / 57

Super-Small Parts Sander

I'm 91 years old, but I still enjoy spending time in the wood shop. I like to make wooden toys and give them to my great-grandkids and charity groups. One trick I've learned over the years is to use emery boards—the kind for filing fingernails— to sand small parts. Emery boards come in different sizes, and some are more abrasive than others, so I keep an assortment on hand. — Joe Aboussleman

37 / 57

Hole Saw Saver

Stuff your hole saw with a moist rag. It will not only keep your saw cooler and the teeth sharper but also extend the life of the saw. Remember to leave room for the depth of the piece of wood you're cutting. When you're finished, dry off the saw to prevent rust. — Scott Nugent.

38 / 57

Use Concrete Forms for Scraps Storage

Short scraps of hardwood are too good to throw away but hard to store neatly. So I bought a 4-ft. tube form made for concrete footings, cut it in half (the cardboard-like material cuts easily) and set the tubes on end. I tack the tubes to a wall or a bench leg so they don't fall over. With the wood scraps stored upright, it's easy to find a piece just the right length. Tube forms are available in various diameters for $5 and up at home centers. — Bill Wells

39 / 57

Need an Awl? Make One

Can awl of us find our awl when we need it? Grab an old, battered Phillips screwdriver and grind the tip into a sharp cone shape on a bench grinder. (Wear eye protection.) Now you have a heavy-duty awl for starting screws and finish nails right on the mark, and chipping dried glue from project corners.

40 / 57

Mustard Bottle is Perfect for Glue

I no longer put up with the messy "over-designed" carpenter's glue dispensers. Instead, I use old mustard bottles; they don't clog and they easily reseal between uses. — Richard Painter.

41 / 57

Pocket-Size Glue Spreaders

When face-gluing boards, use a credit card snipped along its wide edge with a pinking shears. The serrated "pinked" edge spreads the glue like a serrated trowel spreads mastic on floors. Thanks to reader Don Cox for this smooth tip.

42 / 57

DIY Simple and Secure Sanding Block

Not happy with the selection of sanding blocks at the hardware store, I made a few of my own from hardwood scraps left over from a woodworking project. I cut each one to 3/4 in. x 1-1/2 in. x 4-1/2 in.—which is just the right size to wrap a quarter sheet of sandpaper around. And the "kerf" cut helps hold the sandpaper in place until I'm ready to change it. —Tim Olaerts.

43 / 57

Sand Your Hands

Some types of wood filler can be hard to get off your hands after they dry, especially if you use your fingers to push it into small cracks and holes. When that happens, I reach for fine grit sandpaper and sand it off my fingers. It's great for removing dried-on polyurethane glue and canned foam from your hands, too. — Chris James.

44 / 57

Trim Edge Banding with a Chisel

Iron-on edge-banding is a quick way to cover up an edge on plywood. Trimming the excess, however, is tricky. I've tried edge-banding trimmers, but I find the results are unpredictable. With the trimmers I've tried, it wasn't easy to change the direction of the cut to suit the grain direction of the edge-banding. If you're cutting against the grain, you're likely to tear out a chunk of your new edge-banding. Instead, I use a wide, sharp chisel. This way, I can read the grain direction and trim accordingly. Angle the chisel slightly and go slow, raising the back corner of the chisel just enough so that it doesn't dig into the plywood veneer. Smooth the corner with a sanding block after trimming.

45 / 57

Quick Miter Fix

Cutting a miter joint that closes up perfectly and maintains a 90 degree angle is really satisfying. Unfortunately, it doesn't always happen. Here's a quick fix for a slightly open miter joint; rub the shank of a screwdriver along the miter at a steep angle, from both sides of the joint. Chances are, you'll be the only one that knows it wasn't perfect to begin with.

46 / 57

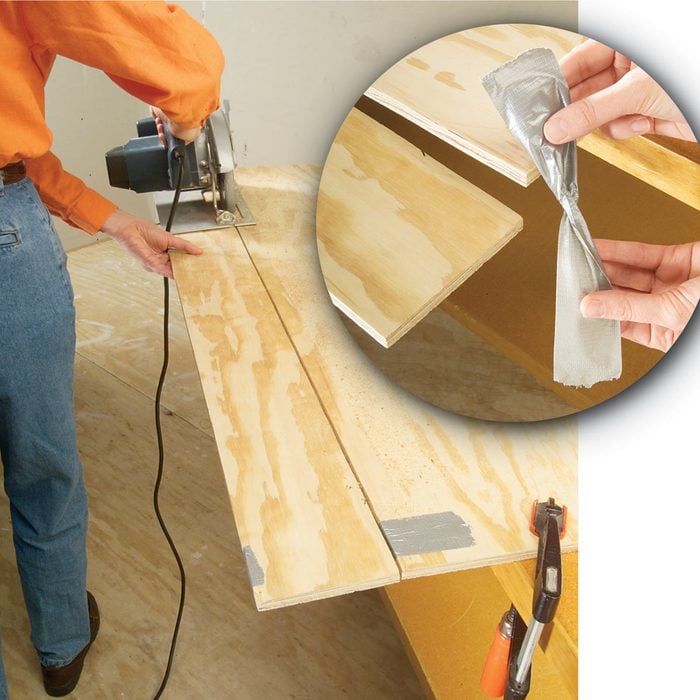

An Extra Hand for Cutting Sheet Goods

Here's a safe and sound way to make long cuts with a circular saw on plywood clamped to a worktable. Cut about 12 in. into the plywood, then twist a piece of duct tape into a bow tie, with up-and-down adhesive faces. Slide it in the saw kerf and press the tape down above and under the plywood. Now as you finish the cut, the trailing end can't curl down dangerously as you saw. Hats off to Mike Connelly for simplifying this job.

47 / 57

Sanding Station for Small Parts

Sanding small items is tricky, as they're hard to clamp in a vise to work on them. So instead of bringing the sandpaper to the workpiece, I bring the workpiece to the sandpaper. I glue sheets of sandpaper to a piece of plywood; 60 and 100-grit on one side and 150 and 220-grit on the other. Spray adhesive works well for this. Since there's sandpaper on both sides, my sanding board doesn't slide around on the bench

48 / 57

What is particleboard?

Particleboard is a manufactured wood product composed of sawdust, wood chips or wood shavings mixed with a resin. This concoction is layered, compressed, subjected to heat and cut to shape, resulting in a sheet material that can be used for a variety of things. It's often used as shelving or as an underlayment for carpet. Plastic laminate may be applied to both sides to create a product that can be used to create everything from furniture to cabinets to wall paneling. Head into IKEA and you'll find acres of particleboard.

There are a few things particleboard is NOT. It's not medium density fiberboard (MDF)—a material with greater density and weight composed of more uniform particles. It's NOT oriented strand board (OSB), a material composed of large wood chips and strands that's structurally equivalent to plywood. It does NOT have great nail or screw holding ability, nor is it all that water resistant; water can quickly cause the material to swell and lose structural integrity. But if you need something flat and cheap for use in a dry place, particleboard will do you proud.

49 / 57

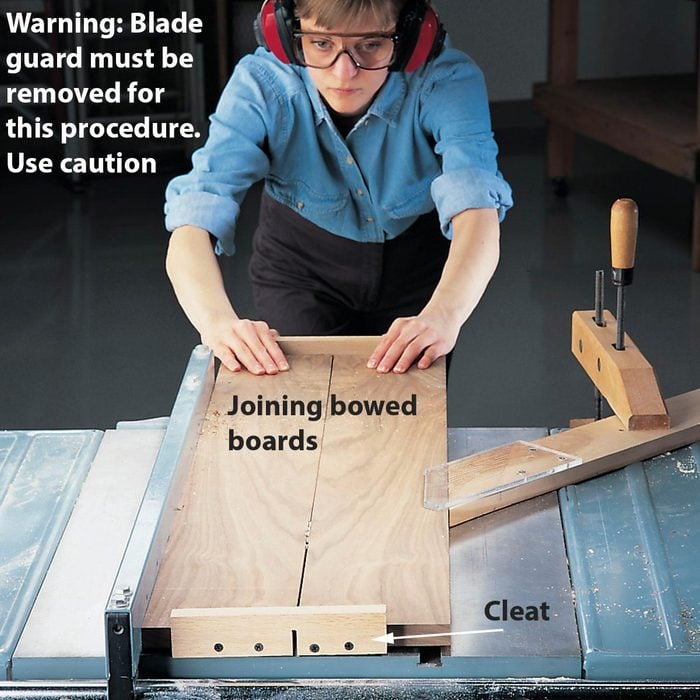

Poor Man's Jointer

Lacking a jointer? Use reader Court Kites' awesome tip to create perfectly matched glue joints on wavy or bowed board edges. Lay the boards on a flat surface, then clamp them across the middle with a bar clamp. Lay two 8-in. long by 1-3/4 in. wide scrap boards across each end and screw them in with four 1-1/4 in. long screws, two per board. Keep the screws well away from your future cutting line!

Set the table saw fence so the blade is centered on the seam, then push the whole thing through the saw. If the board edges are quite bowed or curvy, you may need a second pass. If so, unscrew the cleats, reclamp the boards across the middle center, then screw on the cleats again. The screws ding up the ends of the boards a little, so cut the boards you're jointing a bit long, then trim 1/2 in. from each end to remove the screw holes.

50 / 57

Quick Fix for Dents

Dents in wood surfaces can be annoying. But fret not, they can be fixed. Simply soak a washcloth in water and ring it out a bit so it's not sopping wet. Put the damp washcloth on the affected area. The water will wick through the wood, and that's fine. Now, with your iron on its highest setting, place it on the damp washcloth over the affected area, and make small movements back and forth and in circles. Press down firmly and continue until your wash cloth is dry. It won't take long to evaporate. At this point, the wood fibers are absorbing the water and should expand back to where they were originally. Continue this process and repeat by adding more water until the dents rise up to be flush with the rest of the material.

51 / 57

What is Pocket Screw Joinery?

Pocket screw joinery is a system—employing special drill and driver bits—used to join boards or pieces of plywood to one another. Installing pocket screws involves using a jig to drill a sharply angled, 15-degree hole through the back of one board, then driving a special screw through that hole into the second board to draw them tightly together. It's often used in cabinetmaking and furniture building. The term "pocket" comes from the design of the hole which contains an upper "pocket" for the head of the screw to push against; this pocket also hides the head of the screw.

Pocket screws create a solid, simple-to-make joint. Because of the size and visibility of the hole, it's usually located in areas that are concealed or rarely seen (though special plugs can be used to fill the holes.) Craig Sommerfeld, founder of The Kreg Tool Company, is credited with popularizing pocket screw joinery in the 1980s. The company today is the leader in creating the jigs, clamps and screws used to create pocket screw joints.

52 / 57

Sanding Pad Replacement

The rubber cushion on my old palm sander was wearing thin around the edges. Because of its age, I couldn't find a replacement pad. As I was drinking my beverage with a foam can cover around it, I realized I could cut the foam to fit the sander and glue it on. I peeled off the old pad, cleaned the metal base and attached the foam with contact cement. Works for clamp-on as well as stick-on sanding squares! You can find can covers at discount and convenience stores. — Allen J. Muldoon

53 / 57

Make a Portable Bench Vise

Instead of permanently mounting my 6-in. vise to a workbench, I attached it to scrap plywood so I can clamp it wherever I need it. Stack two pieces of 3/4-in. plywood and screw them together with 1-1/4 in. drywall screws. Mark the vise-mounting holes on the plywood and drill 3/4-in. guide holes through both pieces. Recess the nut by drilling through the bottom sheet with a 1-in. spade bit using the 3/4-in. hole as a guide. Fasten the vise to the plywood with bolts sized to match the vise-mounting holes. If the bolt shafts are too long, cut them off with a hacksaw. — LuAnn Aiu.

54 / 57

No-Slip Sandpaper

Whenever I use sandpaper sheets that are folded in half, the sandpaper slides on itself as I sand. To solve the problem, I just spray a light coat of contact adhesive on the back of the sheet. Once it has air-dried for a couple minutes, I fold the sheet in half for a permanent bond. Works like a charm. — Brian Flynn.

55 / 57

How to Renew Old Epoxy

A while back, I reached for my two containers of epoxy and noticed that the resin in one container had crystallized exactly like honey that's been in the cupboard too long. The solution is exactly the same too: Set the container in a bowl of hot tap water. After about 15 minutes, I emptied the container and refilled it with hot water. After about a half hour, the epoxy regained its normal consistency. Good as new. — Ken Holte

56 / 57

Simple Plywood Cutting Station

When cutting full sheets with my circular saw, I use plastic shelving units as sawhorses. The height is just right and by using three of them, I can make cuts in any direction and the plywood is fully supported. And because the shelving units are made of plastic, I can cut right into them without worrying that they'll damage my saw blade. — John Tinger.

57 / 57

Spare Glue Bottles from the Recycling Bin

Here's a nifty tip—with a nifty tip—from faithful reader Don Ayers: Fill snap-capped sports water bottles with glue and stick them upside down in a hunk of 2×6. Now you don't have to wait for the glue to run into the neck of the bottle, and the cap will control glue flow (and never get lost). To holster the glue dispensers, cut holes in the base with a spade bit that's a smidgen larger than the cap's diameter.

P.S. Be sure to snap the lid closed before returning the bottle to the base. Otherwise the whole bottleful of glue will run out! The snap-cap makes an airtight seal and controls bead size when you squeeze.

Originally Published: February 10, 2021

simmonscappillemper.blogspot.com

Source: https://www.familyhandyman.com/list/56-brilliant-woodworking-tips-for-beginners/

Belum ada Komentar untuk "Being a Woodworker is Easy"

Posting Komentar